DESIGN & INSTALLATION

From our very beginnings in 1946, Koorsen Fire & Security has been helping businesses protect their high-value, high-risk assets such as server rooms, flammable industrial hazards, artwork, and date centers with fire suppression systems. These waterless fire extinguishing systems leave no residue, cause zero damage, and result in very little to zero downtime. From design to installation to continued inspections and service, we will ensure we match the right fire suppression system to your hazard.

INSPECTION & TESTING

Fire suppression systems are typically required to be inspected and tested every 6-months or annually, depending on the type of system. This includes inspecting the initiating devices, release devices, piping, nozzles, cylinders, and signaling devices. Our team of experts understand the importance of a properly functioning suppression system and will work hard to ensure they will be ready if needed.

SERVICE & MAINTENANCE

FIRE SUPPRESSION FAQS

The clean agent is discharged as a gas. The gas is electrically non-conductive and is designed to interrupt the combustion process to extinguish the fire but not damage the sensitive equipment.

A clean agent is inert gases and chemical agents designed to protect data and valuable assets. Once discharged, it does not leave a mess to clean up and will preserve electronics while still extinguishing a fire.

The clean agent is designed to reach a required concentration level in a protected space to suppress a fire. While CO2 suppression systems pose significant health risks, chemical and inert clean agent systems are not harmful to humans at concentration levels. However, leaving the area before the agent is released is highly recommended.

Per NFPA 2001, Standard on Clean Agent Fire Extinguishing Systems, they are required to be inspected twice a year or semi-annually by a certified clean agent technician.

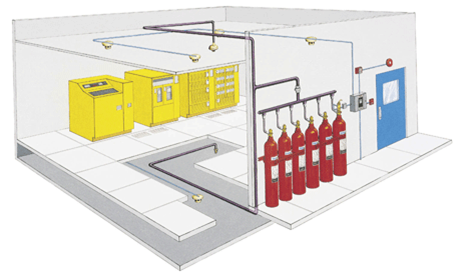

Parts of a Fire Suppression System

Smoke Detectors:

Detects the early stage of a fire and sends a signal to the control panel to activate the suppression system.

Control Panel:

Receives signal from the smoke detectors that smoke is present, activates the notification devices, and activates the release device to suppress the fire.

Notification Devices (horns and strobes):

Are activated when smoke is detected in order to alert people in and around the protected room to evacuate before the suppression system is activated.

Release Device:

Activated by the control panel, the release device is attached to the cylinder and opens up allowing the clean agent to escape from the cylinder and suppress the fire.

Agent Storage Cylinder(s):

The tank or cylinder contains the clean agent designed to suppress the fire. Can be stored as a gas or liquid gas, depending on the agent type.

Nozzles:

The agent travels from the cylinder through the pipes and out the different angled nozzles which disperse the clean agent evenly throughout the protected area.

Abort Switch:

When depressed and held, the abort switch will delay (not stop) the system from activating until everyone has evacuated. It is usually a large button located near the system or near the door of the protected space.

Maintenance Switch:

The switch allows the system to be turned off while technicians perform inspections and maintenance of the fire suppression system.

Manual Release:

To activate the system immediately rather than a typical timed process to allow evacuation, a person can pull the manual release to activate the system.