DESIGN & INSTALLATION

From our very beginnings in 1946, Koorsen Fire & Security has been helping businesses protect unattended fuel outlets, paint booths, transformers, switchgear rooms, and wood finishing operations with dry chemical fire suppression systems. These systems release a dry chemical powder to suppress a fire in a designated space. From design to installation to continued inspections and service, our dry chemical suppression experts will ensure your hazard is protected.

INSPECTION & TESTING

Dry chemical fire suppression systems are typically required to be inspected and tested every 6-months, depending on the type of system. This includes inspecting the initiating devices, fusible links, release devices, piping, nozzles, cylinders and signal. Our team of experts understand the importance of a properly functioning suppression system and will work hard to ensure they will be ready if needed.

SERVICE & MAINTENANCE

FIRE SUPPRESSION FAQS

A dry chemical fire suppression system is activated either manually via a pull station or automatically using fusible links. A dry chemical powder is released into the protected space. Sodium bicarbonate and mono-ammonium phosphate are the most common powders used in a dry chem suppression system.

They are typically required to be inspected every 6-months by a certified clean agent technician. They require maintenance every 6-years and a 12-year hydrostatic test depending on manufacturer.

APPLICATIONS

- Unattended Fuel Outlets

- Automotive and Industrial Paint Booths

- Open Face Spray Booths

- Benchtop Paint Booths

- Paint Mixing Booths

- Power Coating Systems

- Dip and Finishing Tanks

- Transformers

- Switchgear Rooms

- Paint/Flammable Liquid Storage

- Wood Finishing Operations

COVERAGES

Local Application – Overhead or Side

The dry chemical is dispersed from the side or above the open tank hazard.

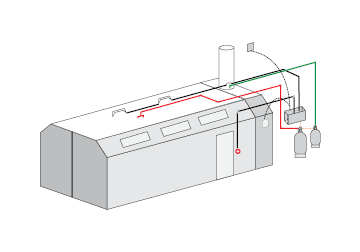

Vehicle Paint Spray Booth (VPSB) Coverage

Systems are capable of protecting numerous booth designs used for spray painting vehicles.

Total Flood

The dry chemical fills the fixed enclosure to protect any hazard within.

Open Front Paint Spray Booth (OFPSB) Coverage

The system protects the hazards in the open booth, the filter bank, and the exhaust bank.